Experts in Precision Micro-Miniature Metal Stamped Parts

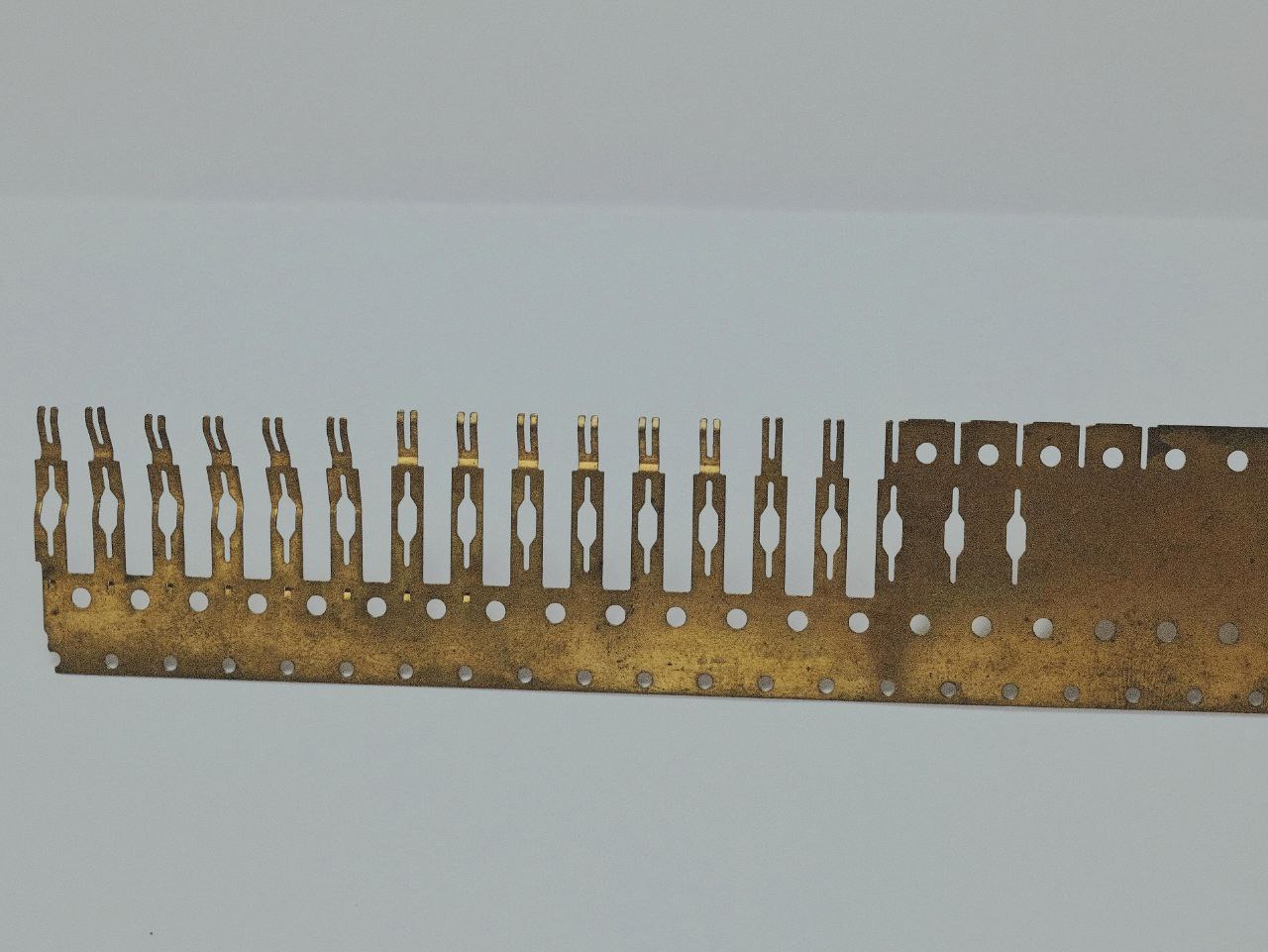

Founded in 1998 by a technocrat with extensive experience in Tool & Die manufacturing, DIETOOL has been delivering exceptional precision components for over two decades. We are committed to providing high-quality, precise stamped and bent sheet metal parts to meet the unique demands of industries such as electronics, telecommunications, switchgear, and automotive.

Our ability to integrate state-of-the-art technology with Swiss-made Bruderer automated stamping machines has established us as the go-to partner for precision metal components. With our expertise, we ensure the total economy and success of our customers.

Tool Technology

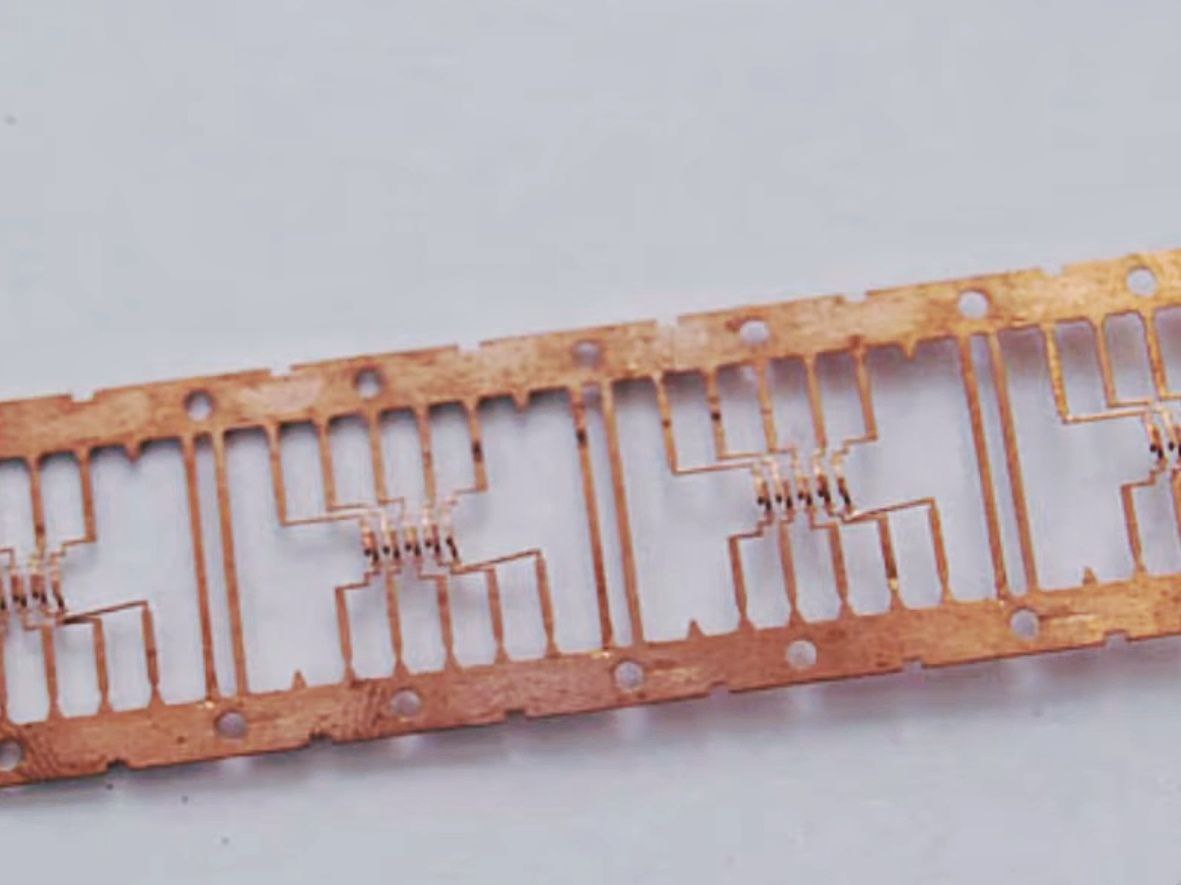

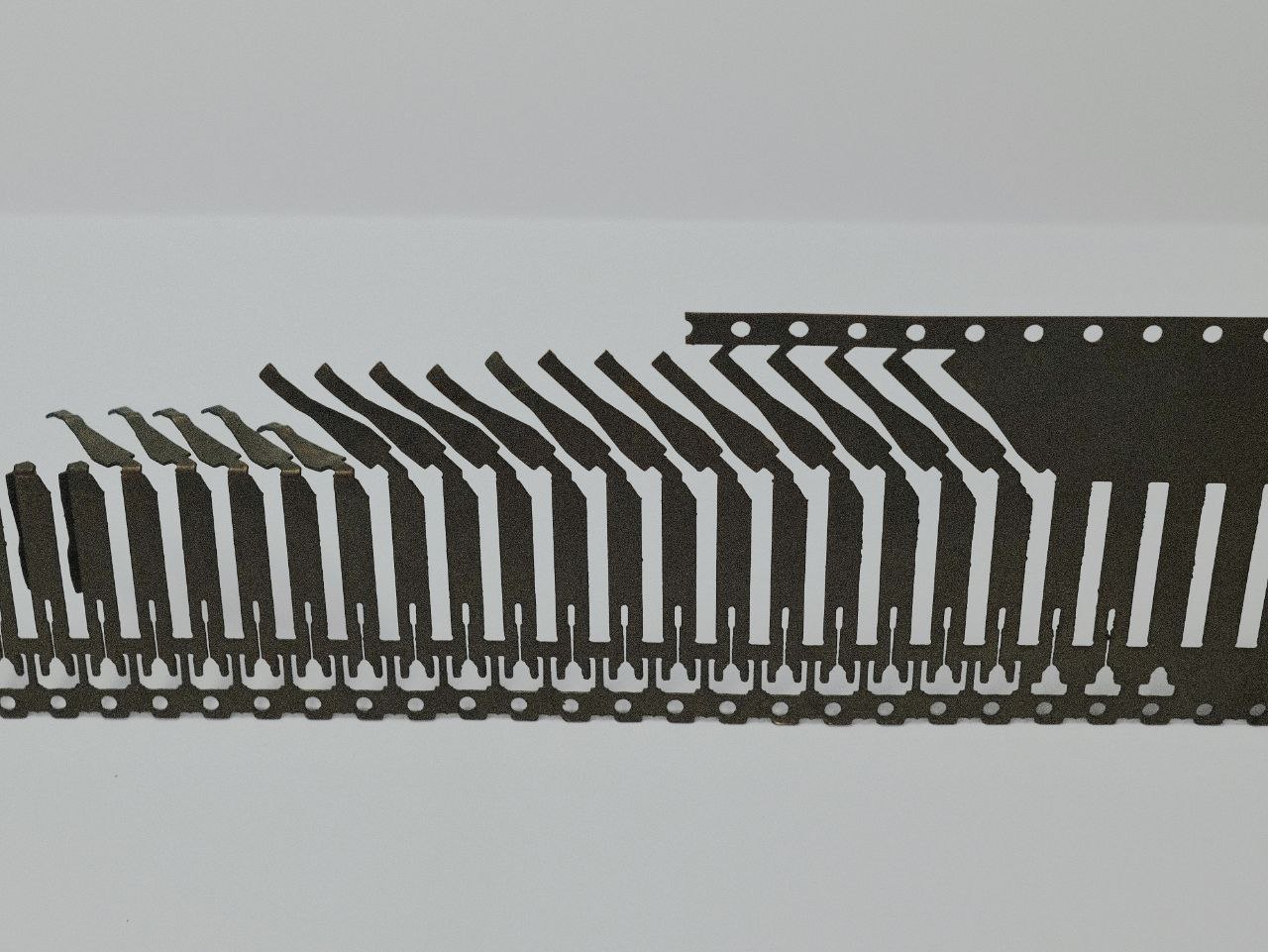

At DIETOOL, we design and manufacture in-house precision tools with accuracy as low as 2-3 microns, ensuring foolproof tool designs and high-volume production without defects.

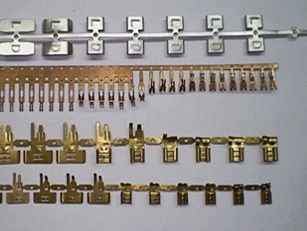

Punching Technology

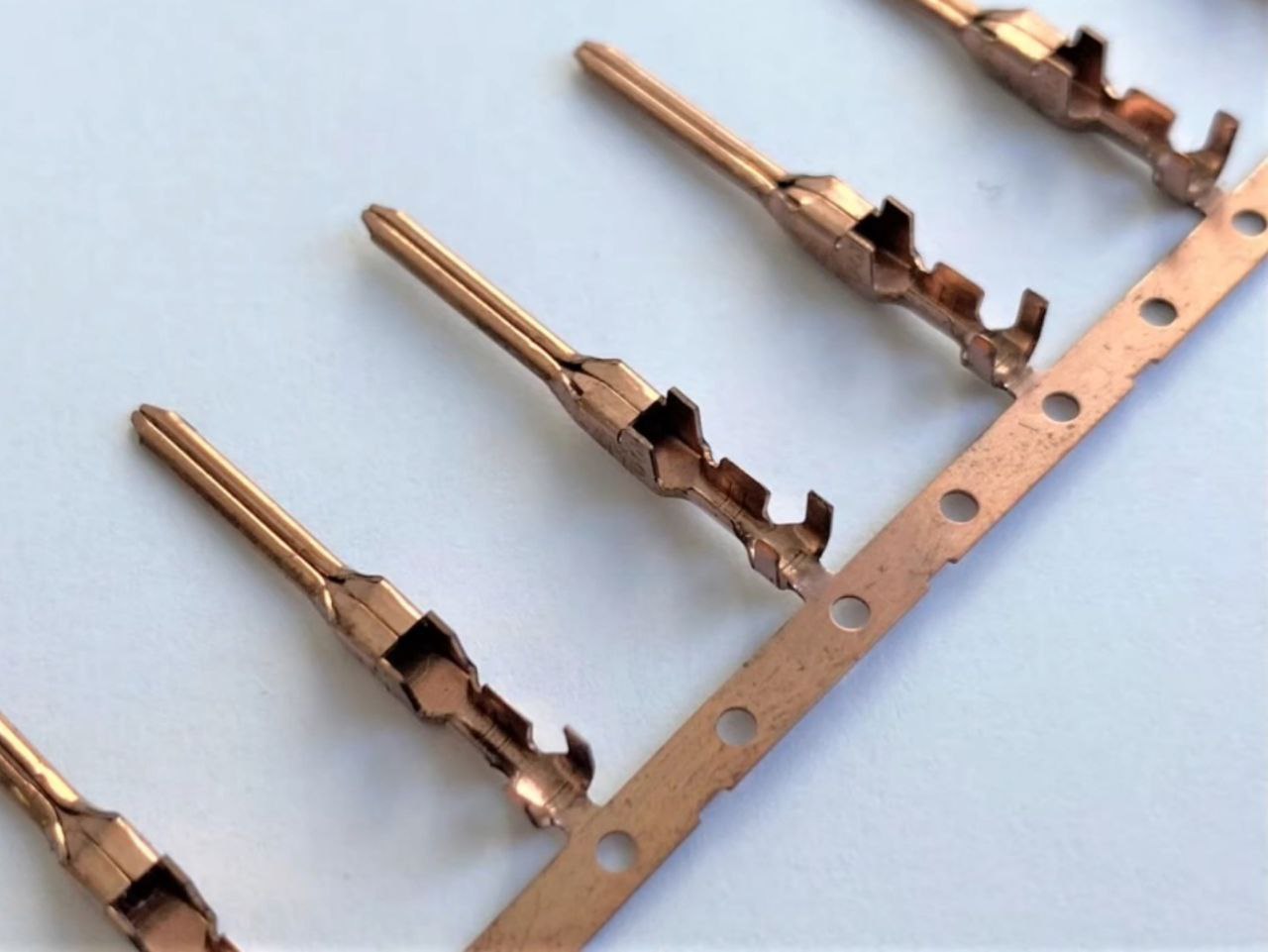

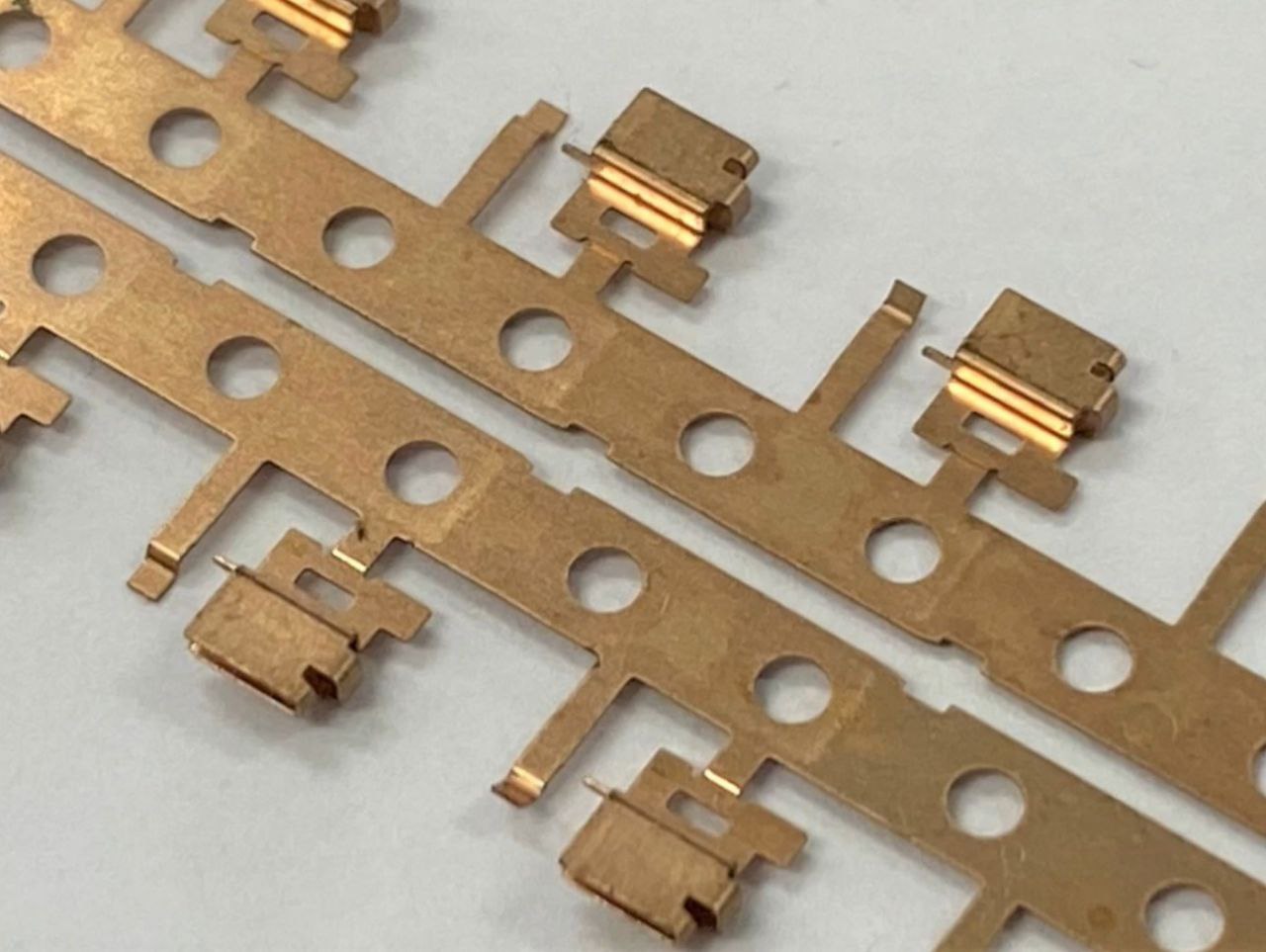

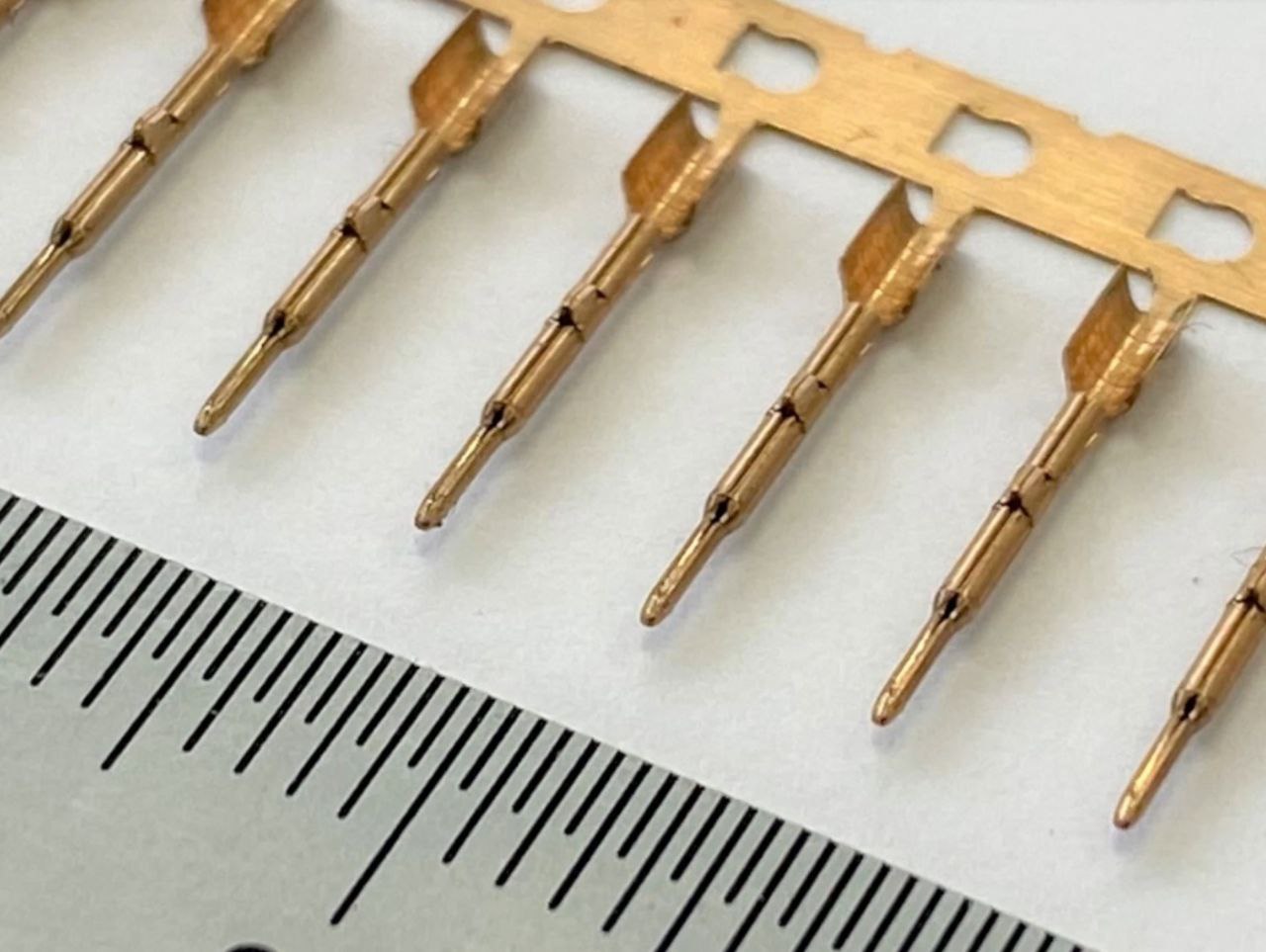

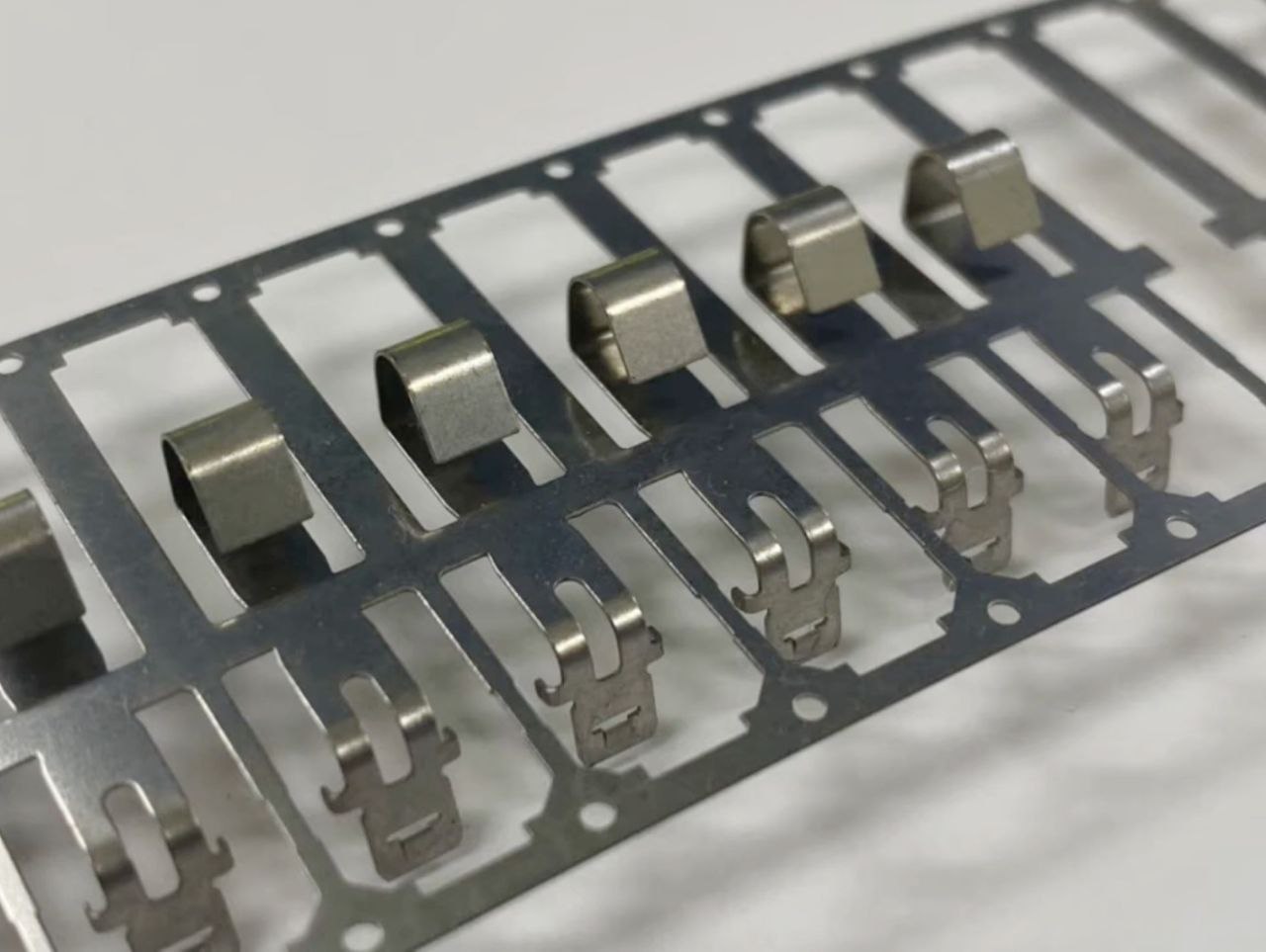

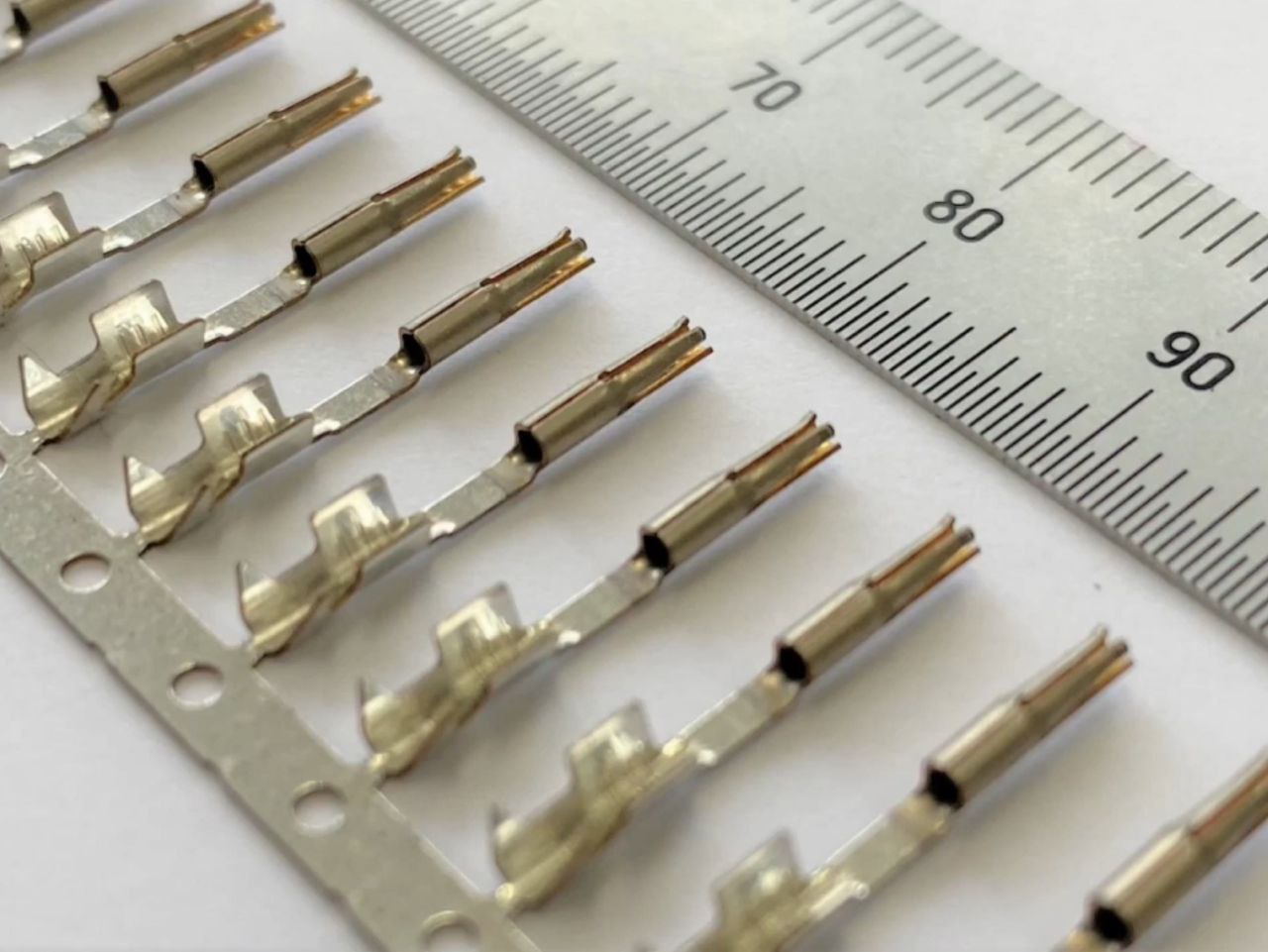

Operating 3 high-speed Bruderer Punching Lines, we produce over 10 million precision-stamped parts monthly, from micro-sized components to palm-sized critical elements, ensuring tolerances as fine as 0.02mm.

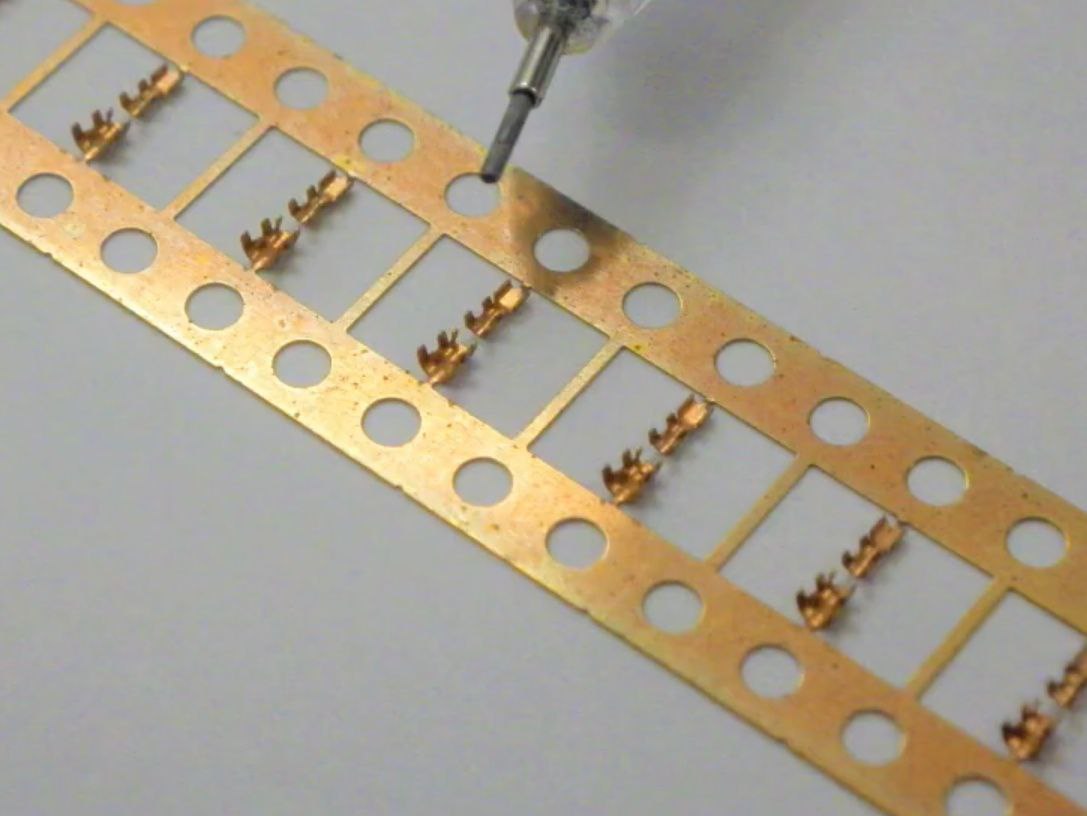

Stamping Assembly

Beyond precision stamping, we provide full component assembly solutions tailored to industry requirements, including over-molding, in-die riveting, semi-auto assembly, hardware insertion, and more.

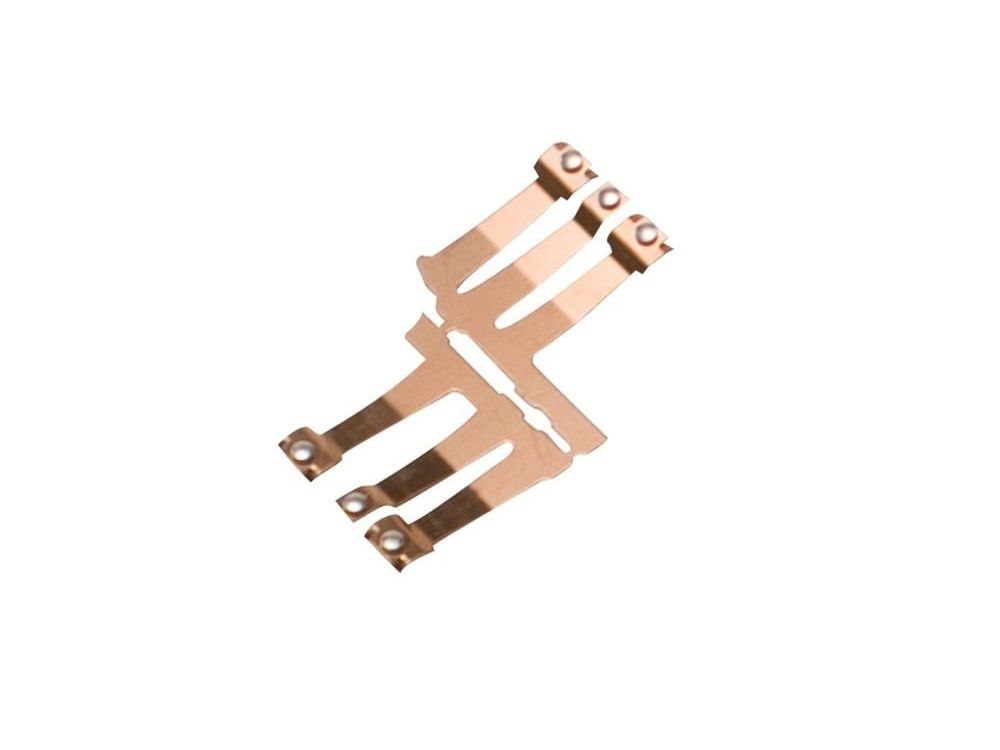

Versatile Material Expertise

We specialize in working with a range of metals, ensuring precision and durability in every component. Our expertise includes

Materials

Copper, Brass, Phosphor Bronze, Beryllium Copper, Aluminum, Stainless Steel, and more

Thickness Range

0.1mm to 2mm.

Advanced Tooling

Optimized techniques tailored to each material's unique properties for superior performance.

OUR MISSION

Our product is not just a product,

but the image of DIETOOL Industries.

This is our Philosophy and business mindset

that every employee shares together.

With utmost attention to Customer Satisfaction,

and in Collaboration with the Customer,

we are Committed to provide Global answers

for Innovative and Quality Standard Parts,

to remain our Customer's Preferred Choice.

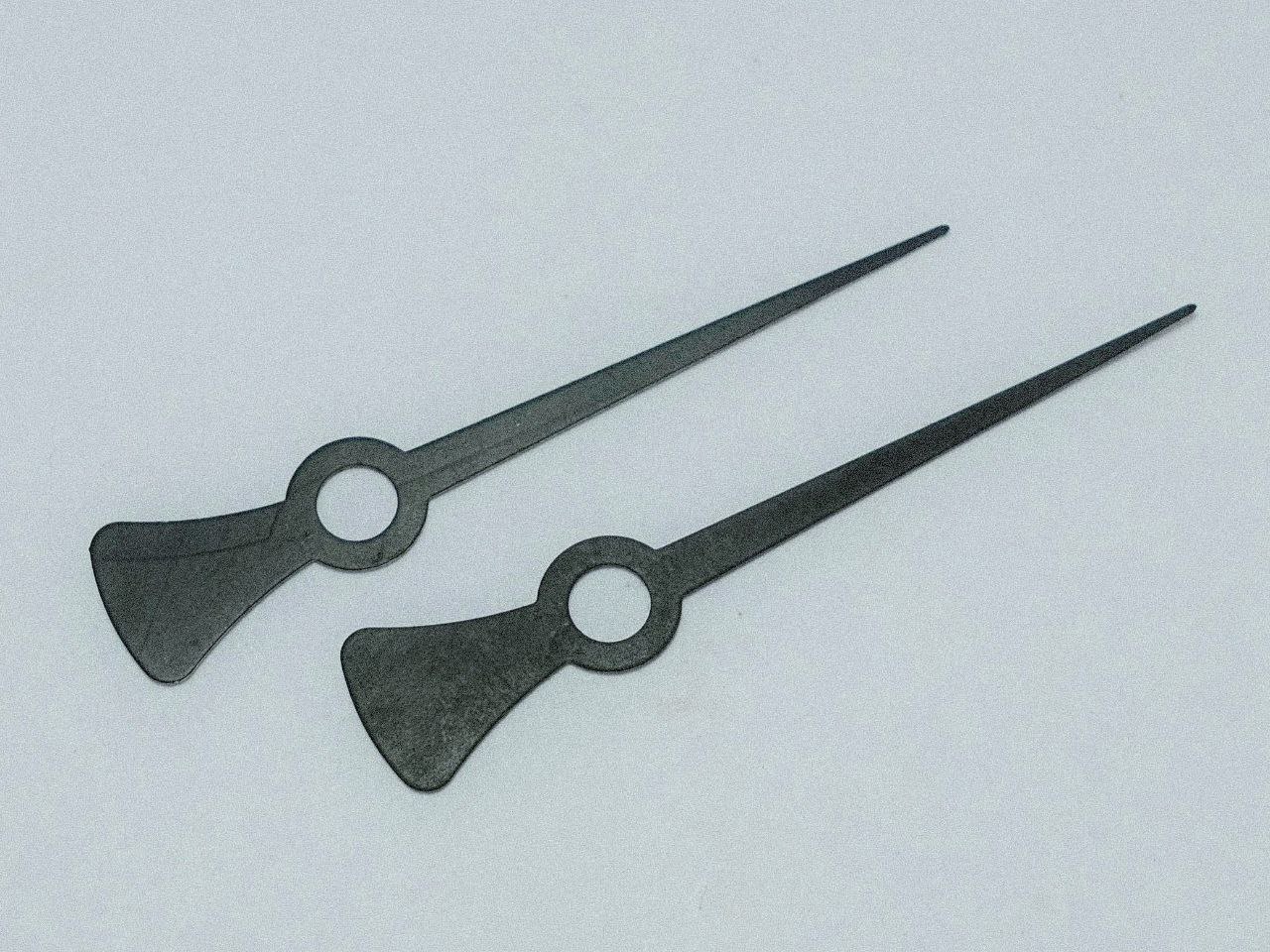

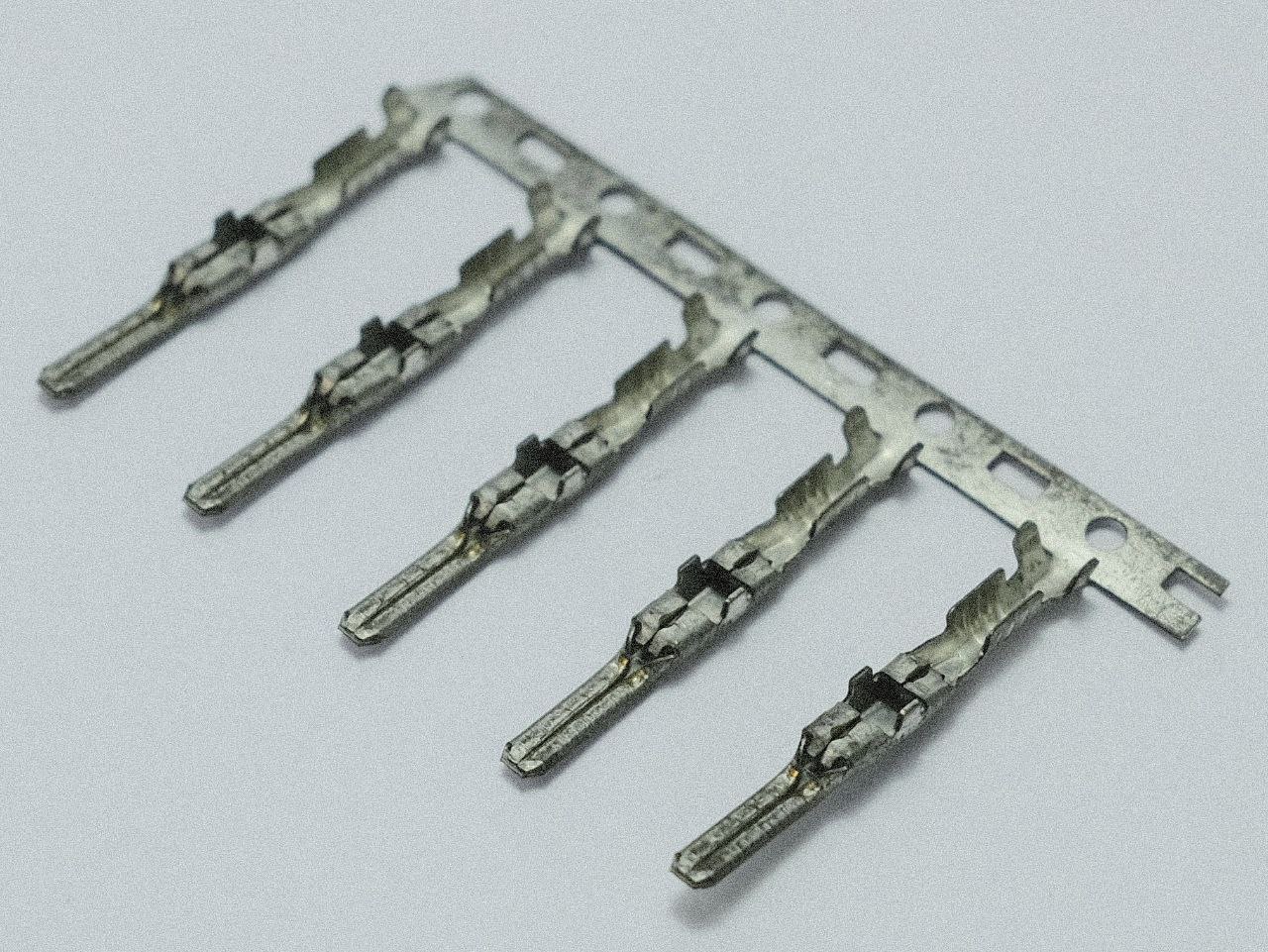

Precision Manufacturing for Every Application

DIETOOL designs and manufactures high-precision progressive stamping tools, delivering customized precision sheet metal stamped and bent parts for demanding applications. Our expertise includes terminals, battery contacts, rotary contacts, lead frames, press-fit pins, wire connectors, bus bars, and more.

14th Source India Electronic Supply Chain

Join us at the 14th Source India Electronic Supply Chain

Date: 18th-19th February 2025

Venue: Chennai Trade Centre, Chennai

Don’t miss out on the latest innovations and trends in the electronic supply chain industry!

Our Products