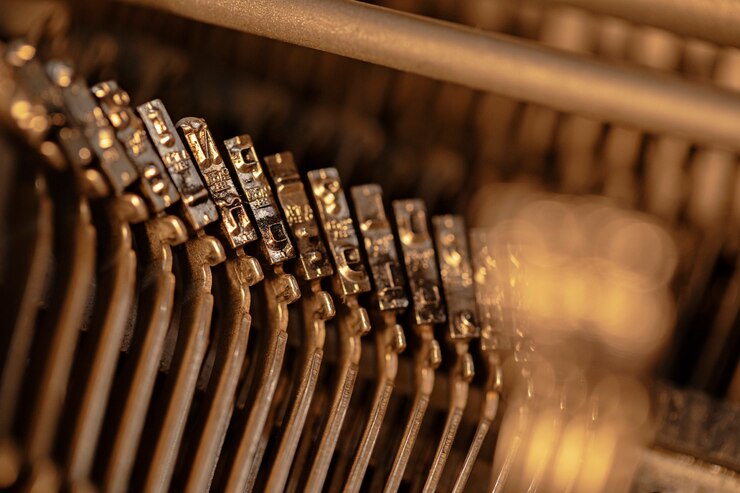

Punching Technology

Engineering Excellence in Precision Metal Stamping

High-Precision Stamping Expertise

Precision stamping has been at the core of DIETOOL’s expertise for over 24 years. With three high-speed Bruderer Punching Lines operating round the clock, we manufacture over 10 million precision-stamped parts every month.

Versatile Stamping Capabilities

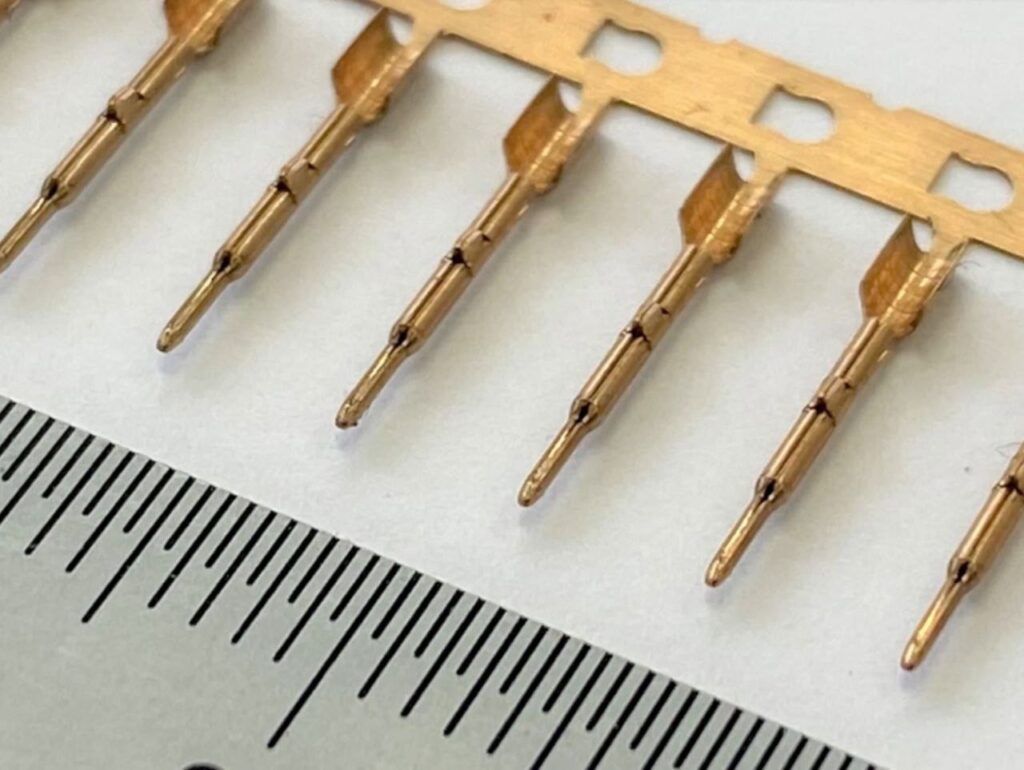

At DIETOOL, we produce stamped parts ranging from micro-sized components, as small as a grain, to larger components fitting in the palm of your hand. These tiny components play a crucial role in various industries, requiring extreme precision in form and geometry.

Mastering Precision for Perfection

To meet tight tolerances of up to 0.02mm, our manufacturing process leaves no room for error. We employ:

- State-of-the-art precision tooling

- Automated high-speed stamping machines

- Strict quality control measures

Why Choose DIETOOL?

- Ultra-precision stamping with micron-level accuracy

- High-speed, large-volume production

- Custom stamping solutions for various industries

- Advanced technology ensuring defect-free components

See What Else We Offer

Tool Technology

Tool Technology

At DIETOOL, we design and manufacture in-house precision tools with accuracy as low as 2-3 microns, ensuring foolproof tool designs and high-volume production without defects.

Click Here

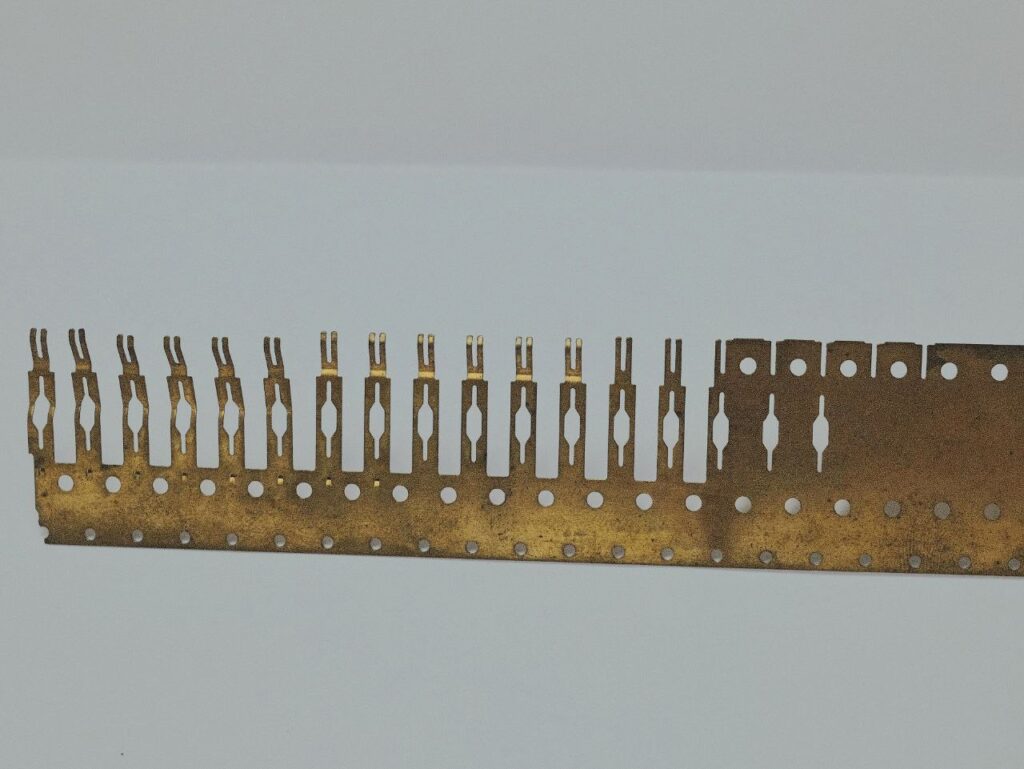

Punching Technology

Punching Technology

Operating 3 high-speed Bruderer Punching Lines, we produce over 10 million precision-stamped parts monthly, from micro-sized components to palm-sized critical elements, ensuring tolerances as fine as 0.02mm.

Click Here

Stamping Assembly

Stamping Assembly

Beyond precision stamping, we provide full component assembly solutions tailored to industry requirements, including over-molding, in-die riveting, semi-auto assembly, hardware insertion, and more.

Click Here