What we do

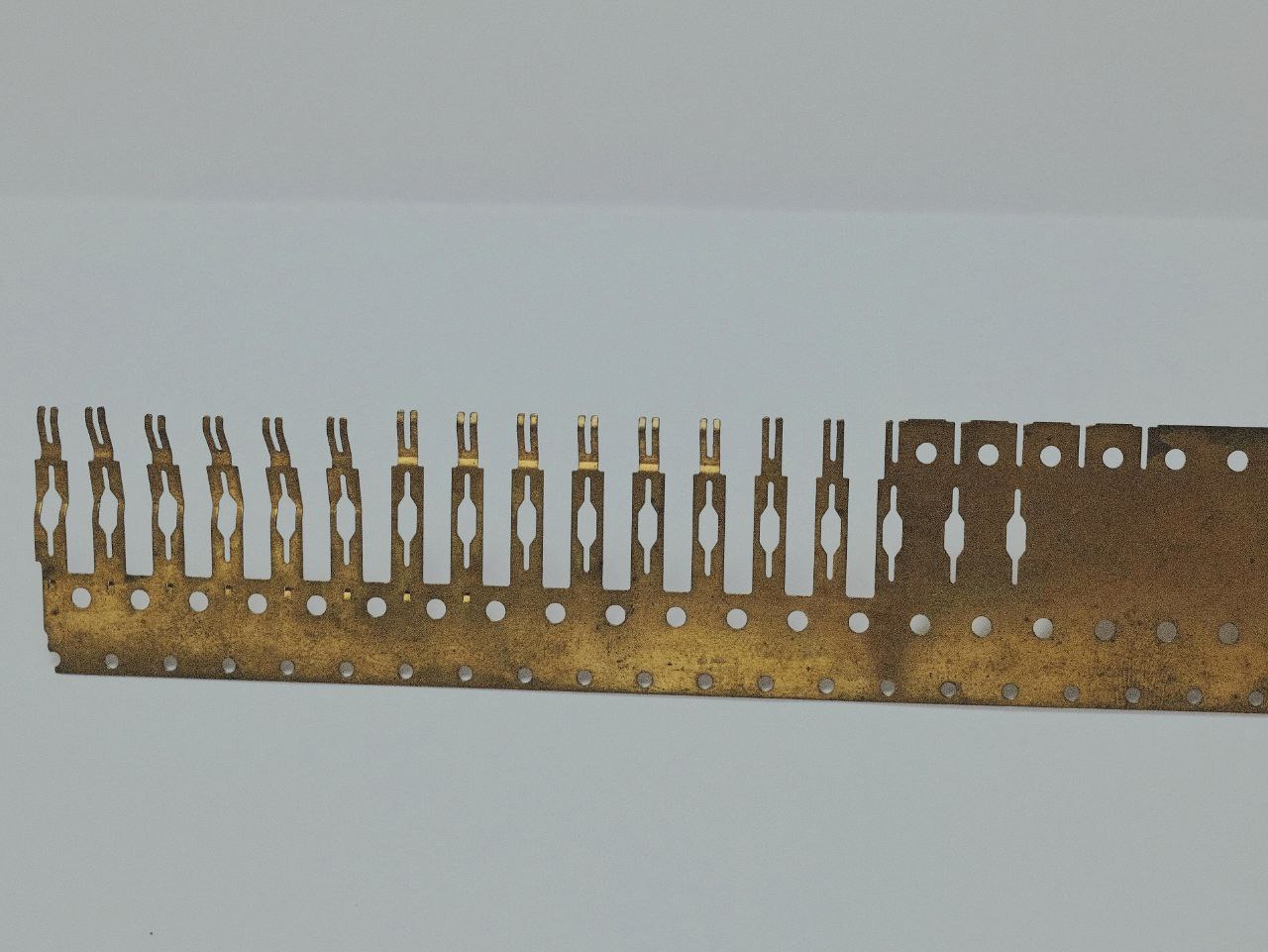

Expertise in high-precision automated progressive stamping tools and customized sheet metal components.

High-Precision Tooling for Uncompromised Quality

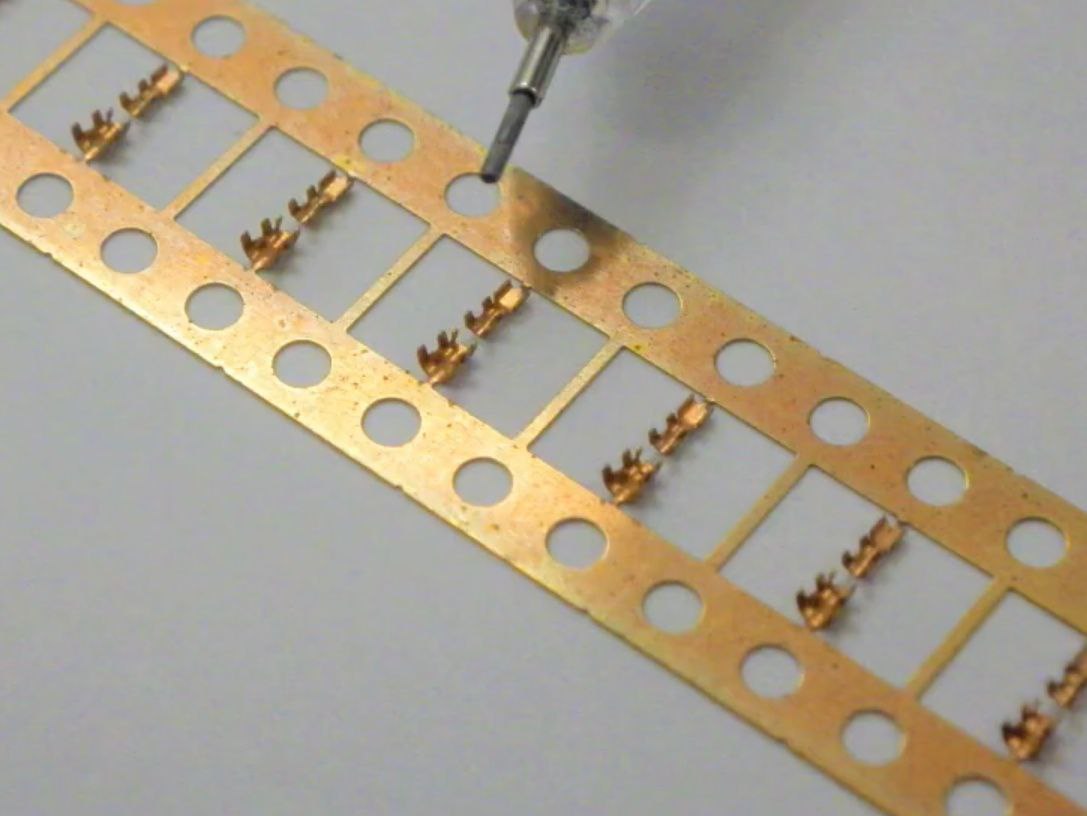

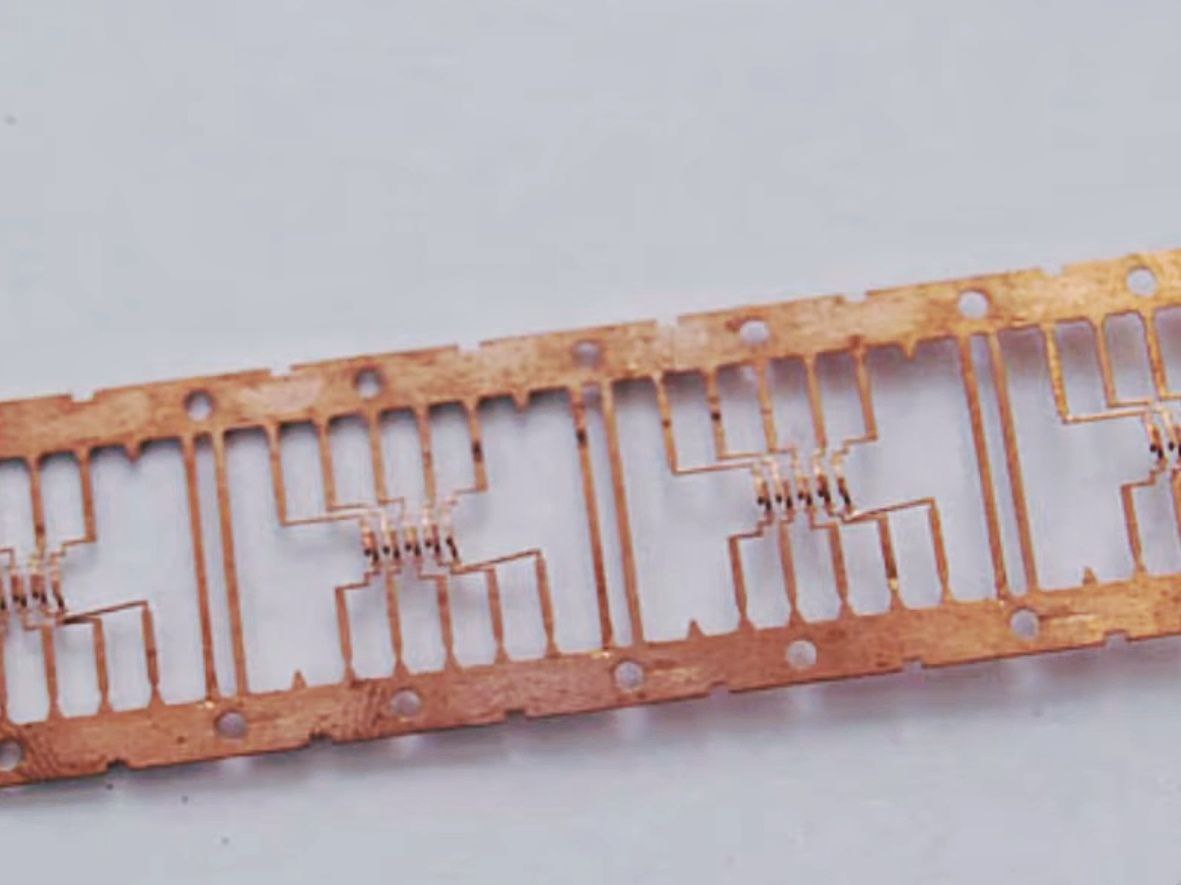

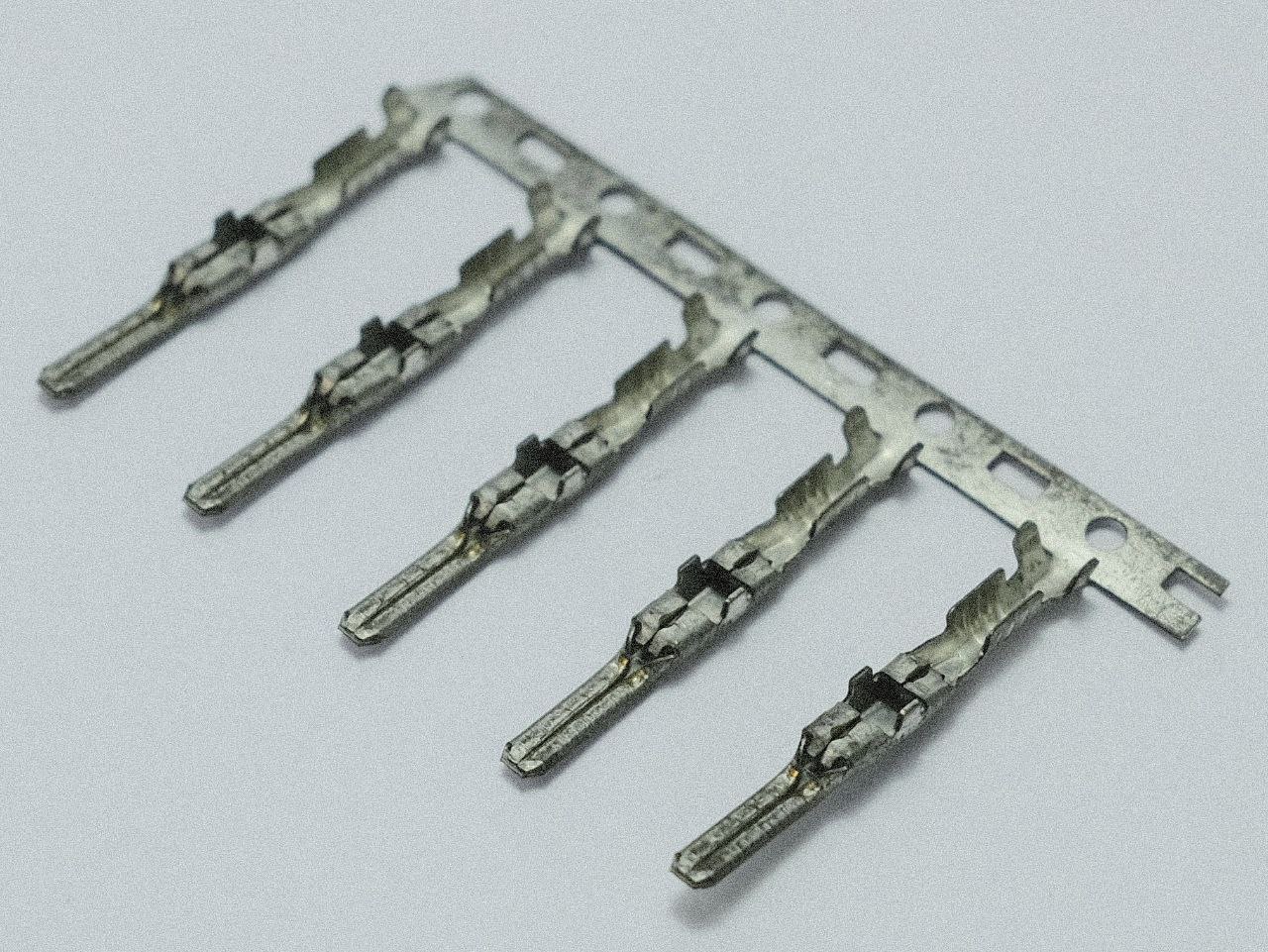

Since its inception, DIETOOL has been seriously engaged in designing & manufacturing high precision automated progressive

stamping tools, for providing Customized Precision sheet metal stamped and bent parts for various demanding applications.

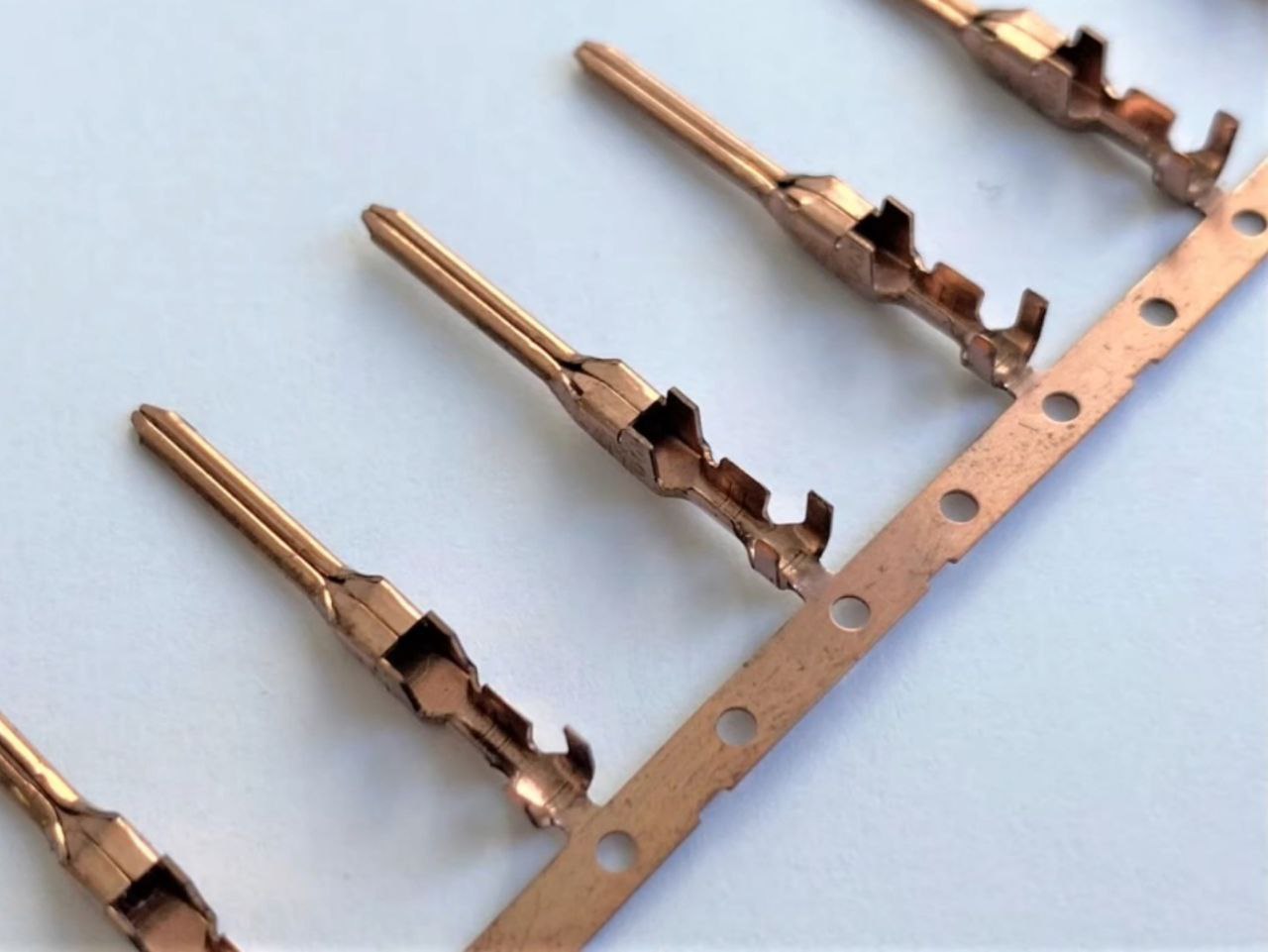

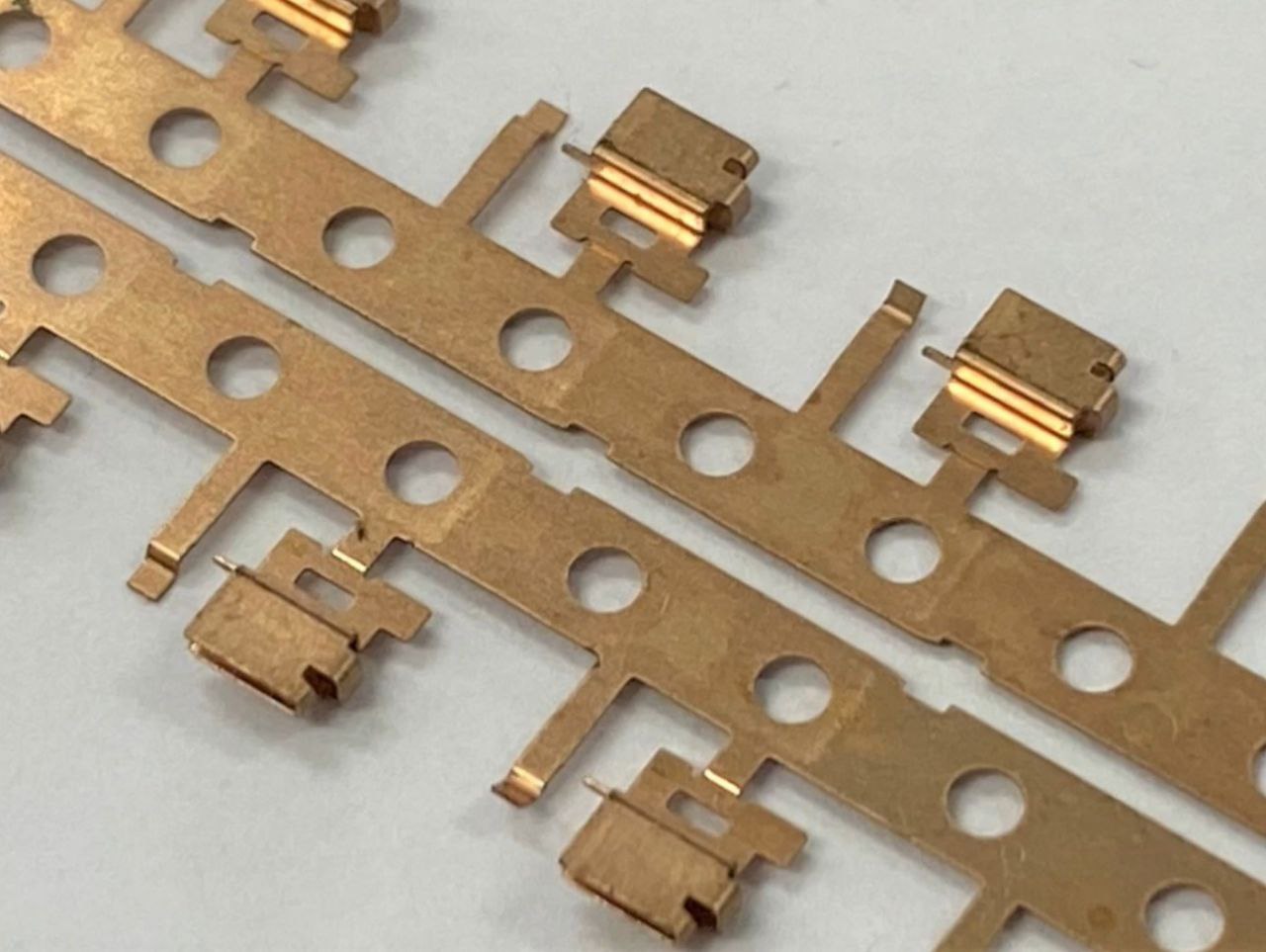

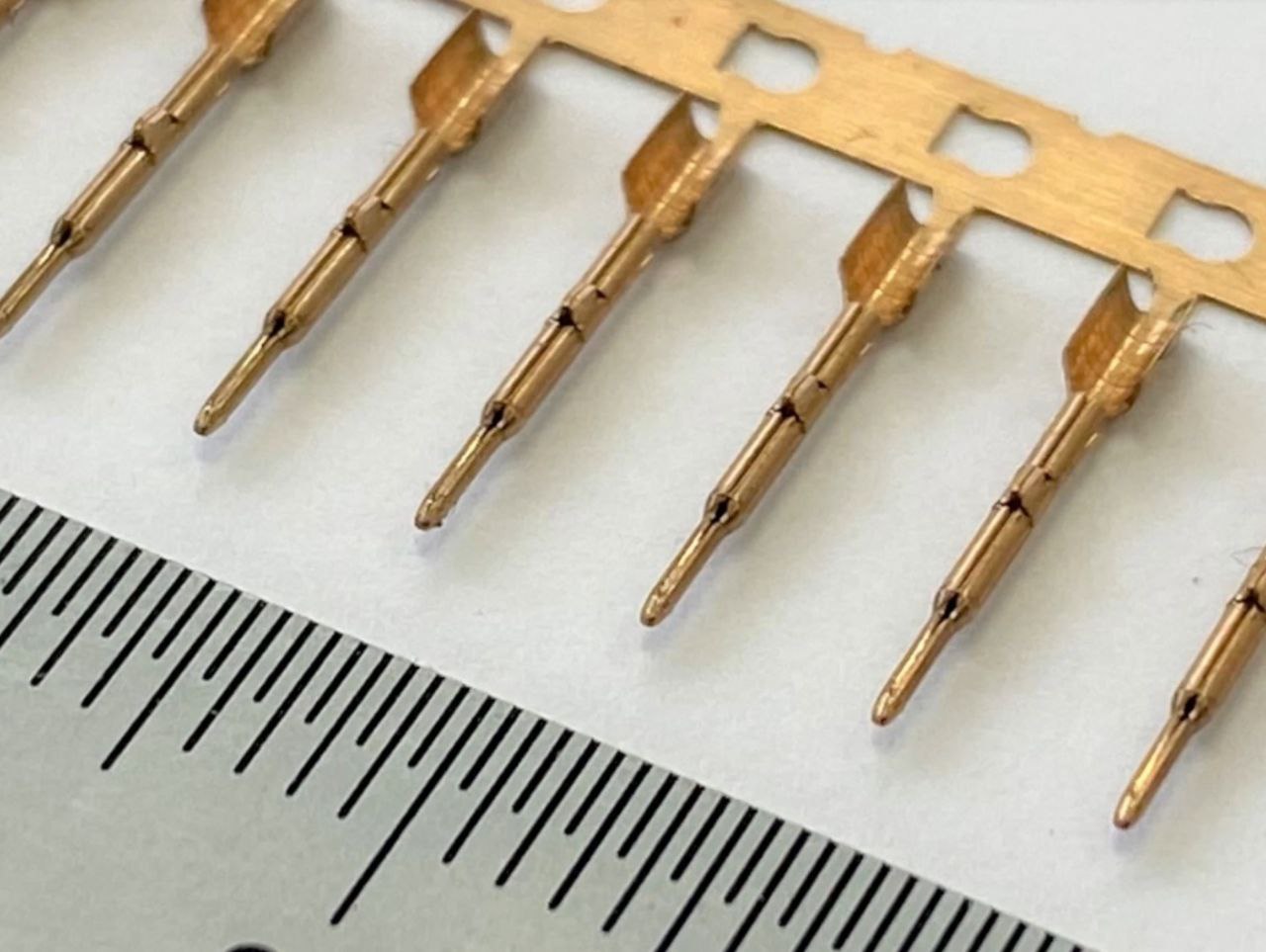

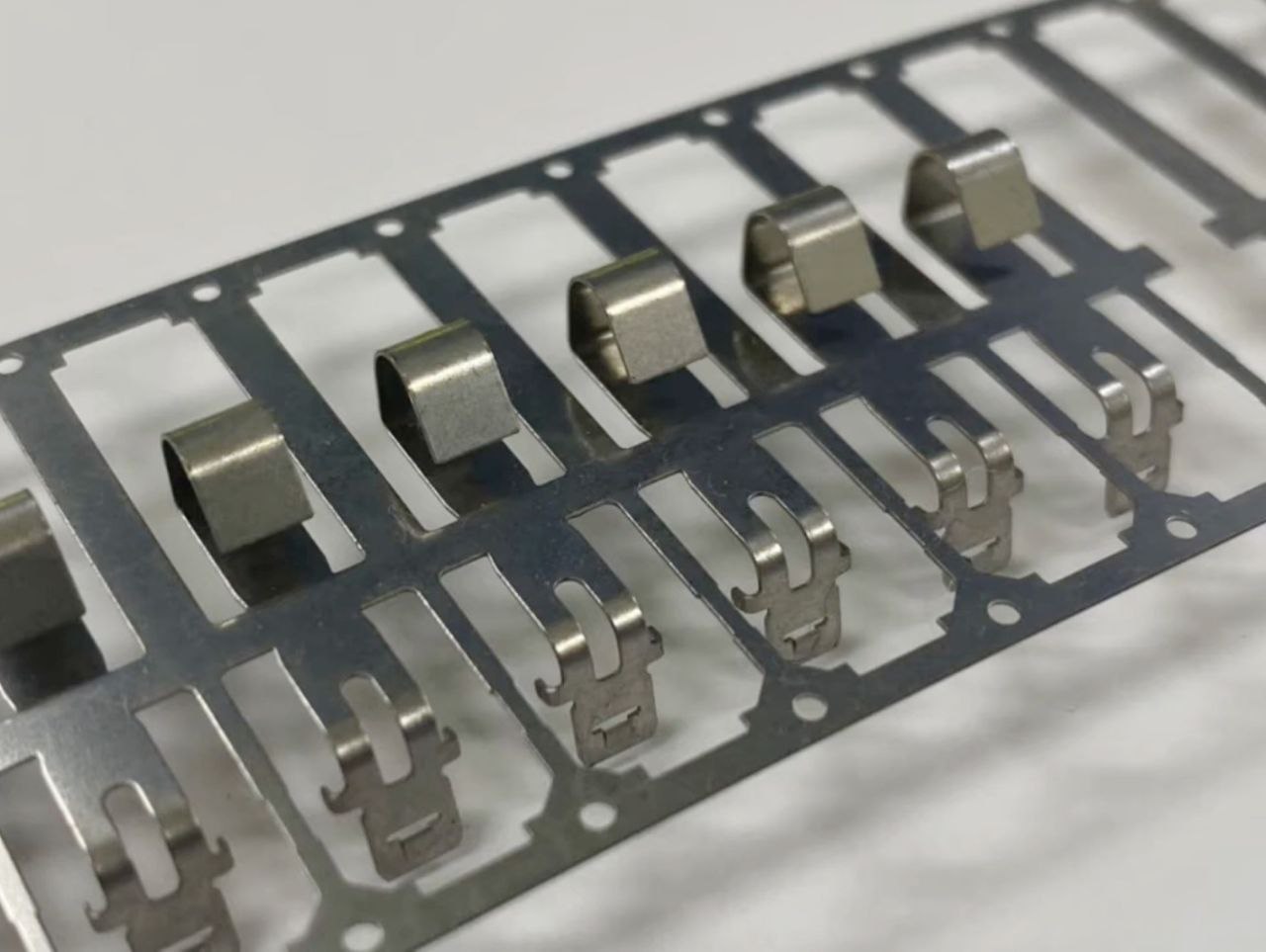

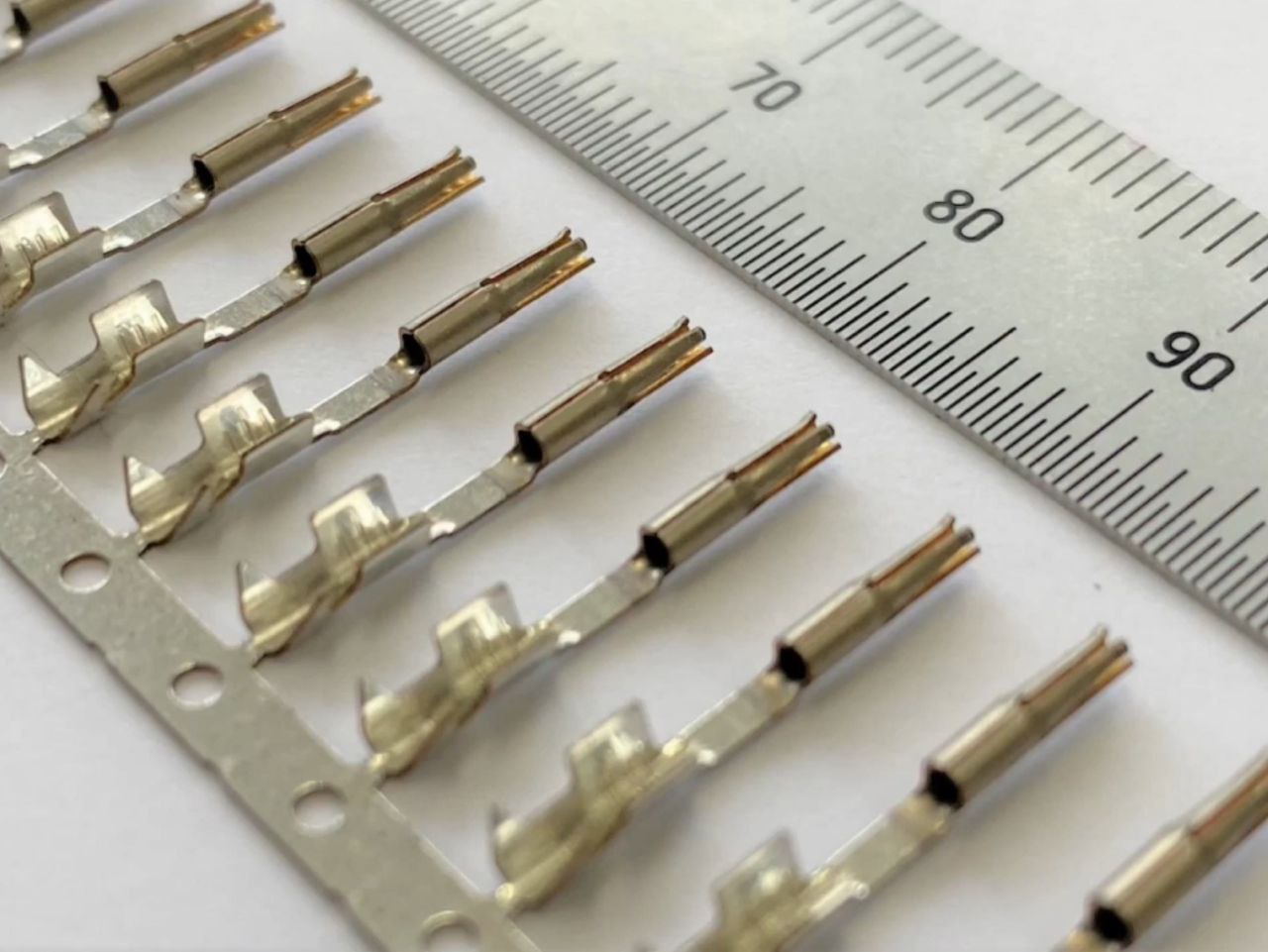

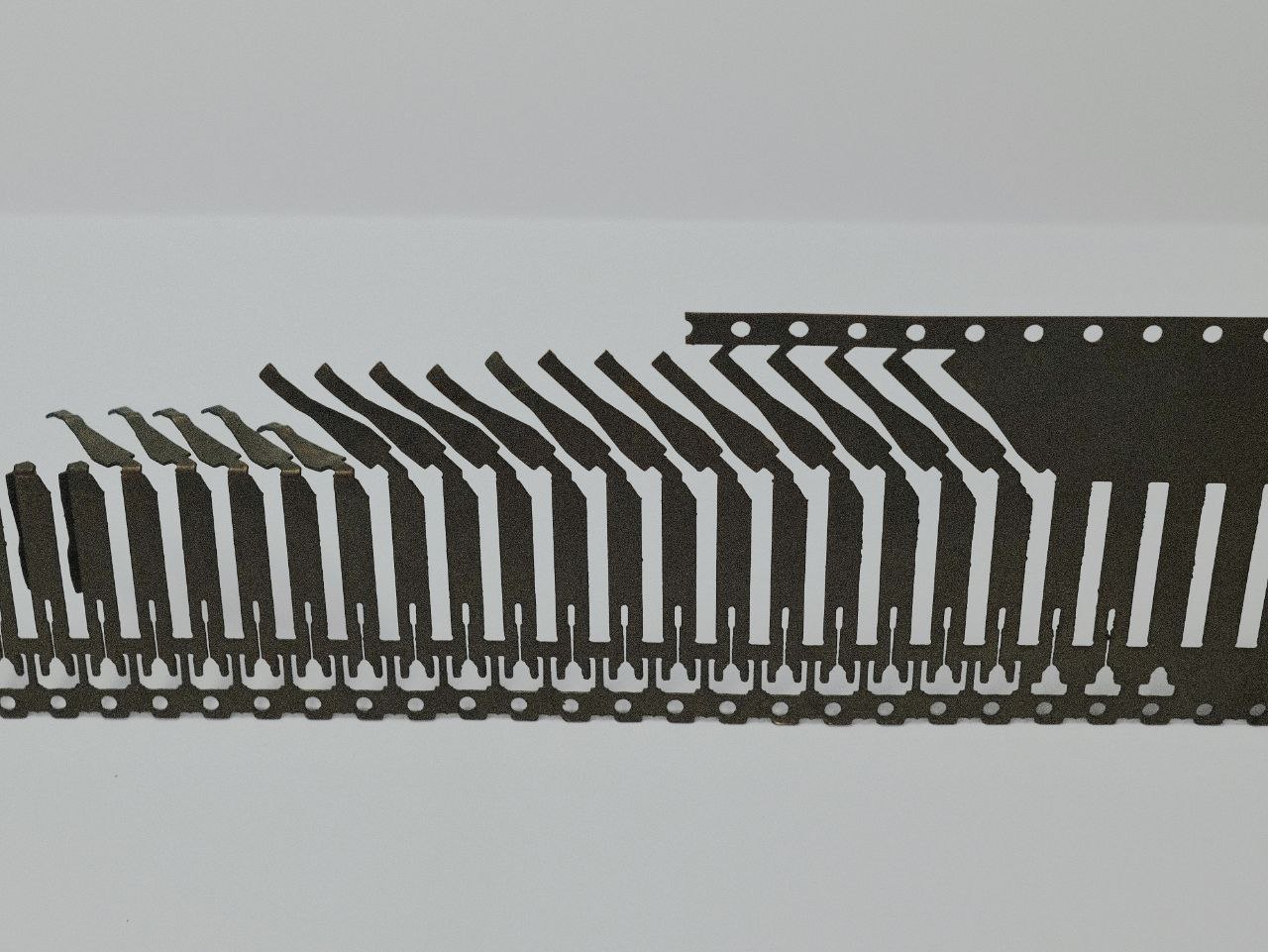

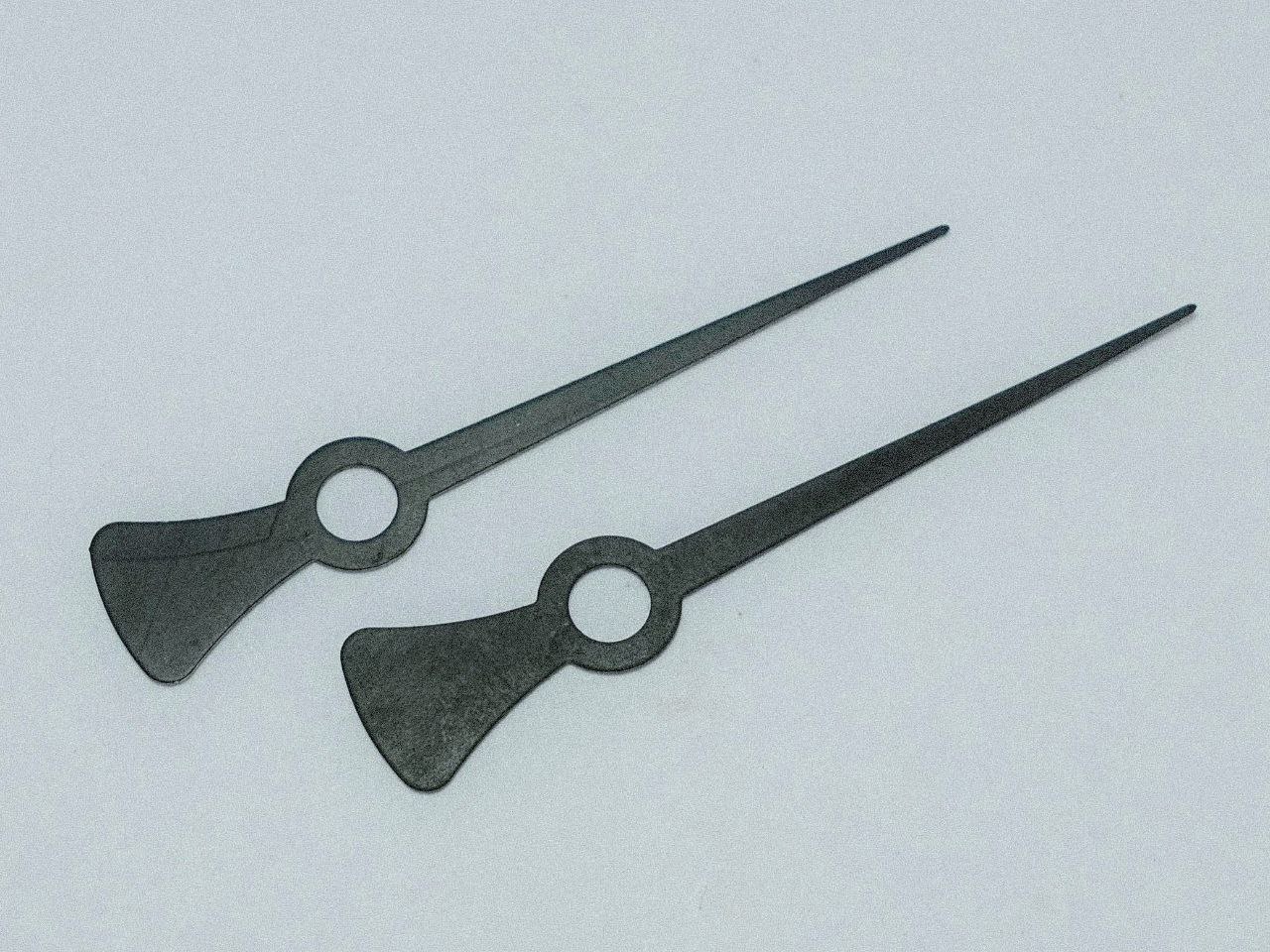

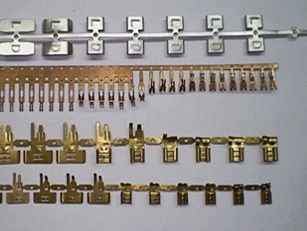

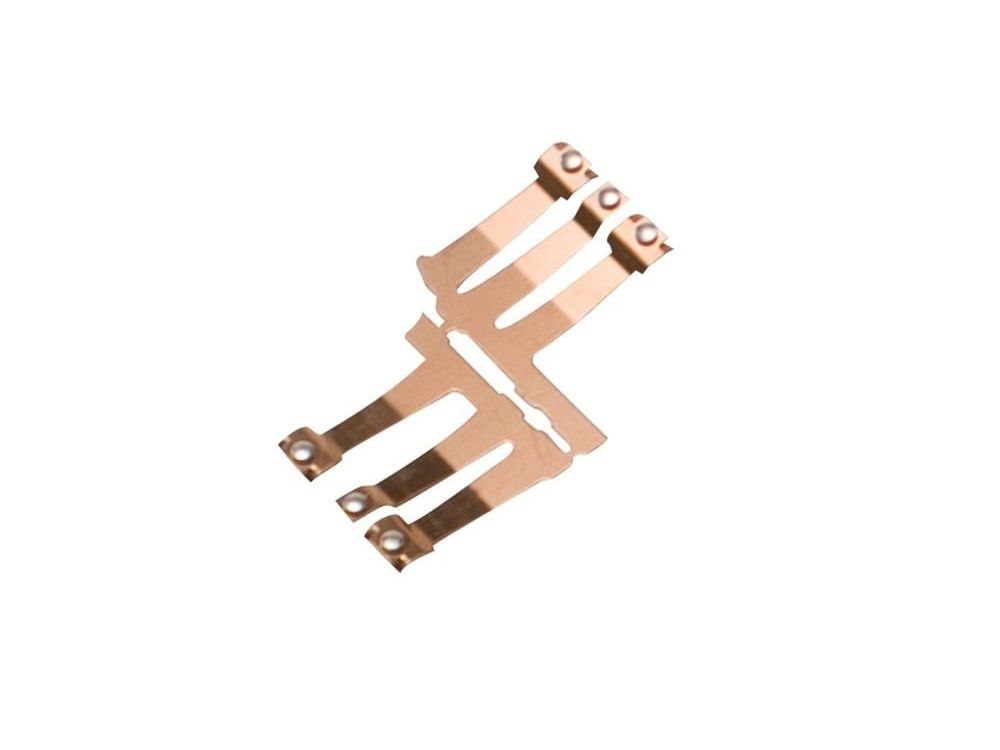

DIETOOL Product range includes various Customized Precision Components such as: Terminals, Battery Contacts, Rotary Contacts, Moving Contacts, Lead Frames, Press fit Pins, Wire Connectors, Wire Harness Terminals, Bus Bars, Shields, etc.

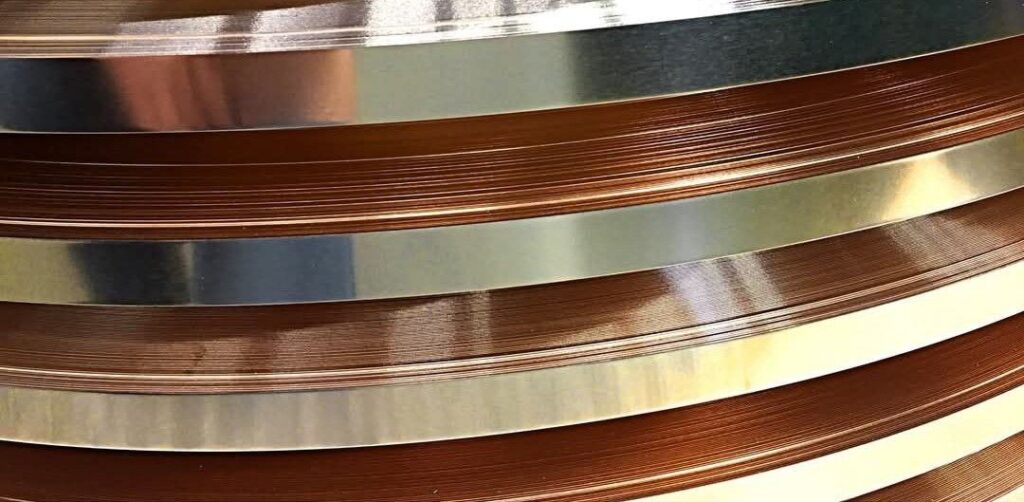

Component Material Capability

Although each metal has its own blend of mechanical, chemical and surface properties, our decades of experience and can achieve optimum results from a variety of metals. Our team develops the right tooling techniques to ensure the unique properties of any metal are yielding exactly what our customers require for their metal stampings. And it is this capability that makes DIETOOL Stand-Out from the rest. No concept or material is a bottleneck to DIETOOL’s ability to offer the right solution. Most varieties of metals can be accommodated down to 0.1mm thickness, up to 2mm. Material types we commonly work with include: Copper, Brass, Phosphor Bronze, Beryllium Copper, Aluminum, Stainless Steel, Steels, Carbon steels.

Our Products